- Main

- Technologies and developments

- Well heating unit «FONTAN»

Well heating unit «FONTAN»

Wax crystallization and

While developing oilfields with high viscosity and waxy oils, the following issues comes to the front:

- Weak inflow of formation fluid;

- Tubing flow capacity decrease due to wax accumulation;

- Pipeline flow capacity decrease due to wax accumulation.

A plenty of various methods (mechanical, chemical, thermal), are being used for struggling against accumulation of wax in the tubing of

The exact given problem is solved by means of stationary Well Heating Unit, actually an electro cable heating unit and its modifications intended, first of all, for prevention wax accumulation by such a method which allows to warm up the internal space of the tubing and to maintain fluid temperature above those of firm wax and hydrate accumulation. Operating principle is to heat tubing inside space with a purpose heating cable located in the area of intensive wax accumulation.

Our company executes design, manufacturing, sale and after sales services of the WELL HEATING UNITS (WHU’s)

WHU’s is most effective remedy wax and

WHU’s modifications developed by NEFTESERVIS LLC

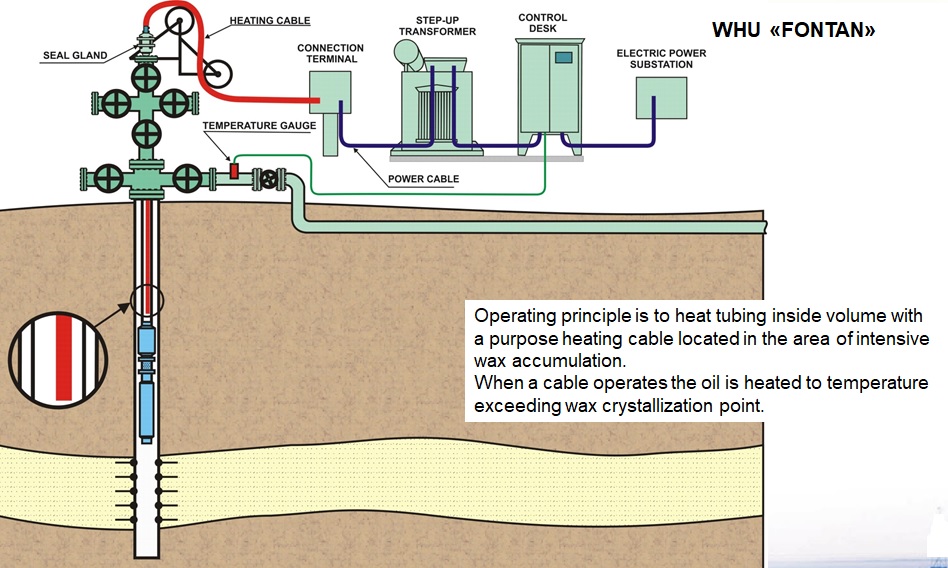

WHU «FONTAN»

It is designed to heat wells with a heating cable located inside of tubing.

Operating principle is to heat tubing inside volume with a purpose heating cable located in the area of intensive wax accumulation. It is designed for well equipped with ESP, progressive cavity pump with submersible electrical motor, natural flow, gas lift types.

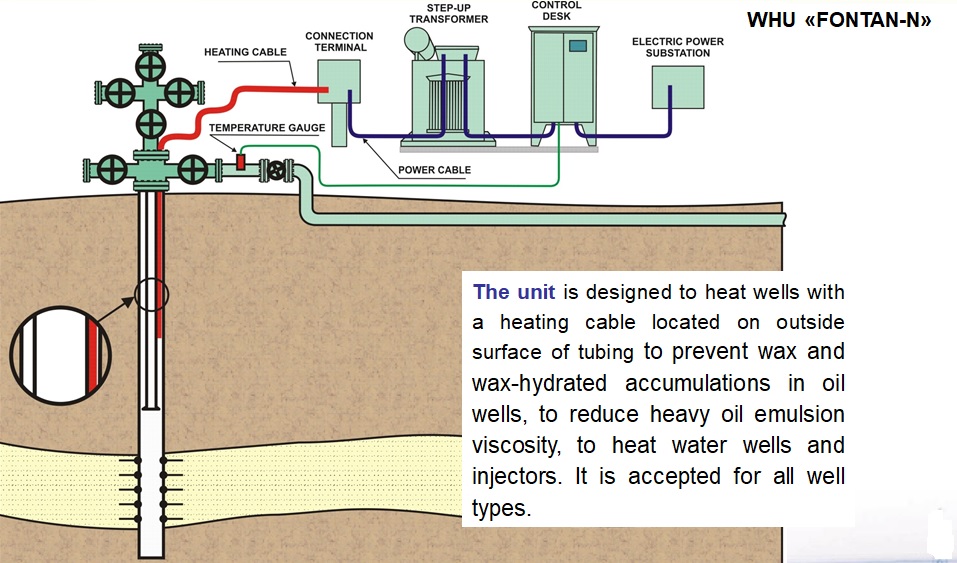

WHU «FONTAN-N»

It is designed to heat wells with a heating cable located on outside surface of tubing.

The unit is designed to heat wells with a heating cable located on outside surface of tubing to prevent wax and

Standard set of equipment:

- Нeating cable;

- Control desk with spare parts;

- Well head packer;

- Connection terminal;

- Wellhead wired temperature gauge;

Additional set of equipment:

- Wellhead RIH/POOH heating cable device;

Step-up transformer (if cable length is more than 1200m — 1300m);- Draw works;

- Cable forced RIH device.

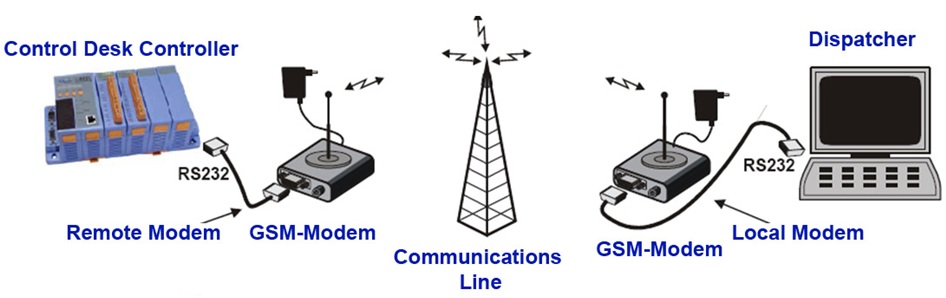

Equipment of the control desk allows for data transmission to a dispatch control room or personal computer. In this regard it is possible to remotely monitor heating parameters

Data can be transmitted through one of the following communication channels:

- Through a wire link using a modem;

- Through cellular communication operators using

GSM-modems or any other protocol; - Through ethernet port.

During work of the cable the oil liquid is heated up to the temperature exceeding temperature of crystallization of wax. Thus it provides:

- Permanent cleanness of tubing inside volume,

X-mass tree and adjacent flow lines; - Increasing of capacity and overhaul life of ESP;

- Operating continuity for a well and flow lines;

- Exclusion of necessity for other

de-waxing operations; - Environmental safety around a well;

- Easy well operation;

- Decreasing of oil losses and increasing a well utilization rate;

- Continuous well operation in remote areas and wells producing high viscosity oil.