- Main

- Technologies and developments

- Bottom-Hole Area Heating Unit

Bottom-Hole Area Heating Unit

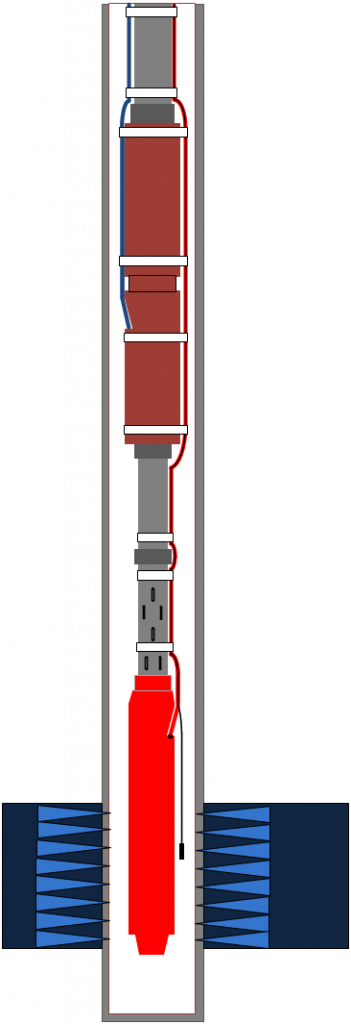

Heating Unit consists of electrical downhole regulable resistance heater fixed to tubing which is fixed to lower part of downhole equipment. In dependence on recovery mechanism (mechanical, electrical, natural flow, gas-lift) downhole heater has the shape of cylinder with a ribbed surface that brings to uniform heating of borehole fluid and borehole environment.

Power supply is conducted through three-core armoured cable with high-temperature cable lengthener which provides durable tight connection.

PROCESS CONTROL

Heater monitoring and heating control is carried out by an automatic heating control station which enables to maintain temperature of heater within specified schedule depending on operating mode of the well. Power cable providing power supply to a heater, has measuring conductor to monitor a heater temperature, and can have embedded temperature detector with required quantity of additional measuring conductors to monitor temperature of liquid going from a heater.

Heater monitoring and heating control is carried out by an automatic heating control station which enables to maintain temperature of heater within specified schedule depending on operating mode of the well. Power cable providing power supply to a heater, has measuring conductor to monitor a heater temperature, and can have embedded temperature detector with required quantity of additional measuring conductors to monitor temperature of liquid going from a heater.

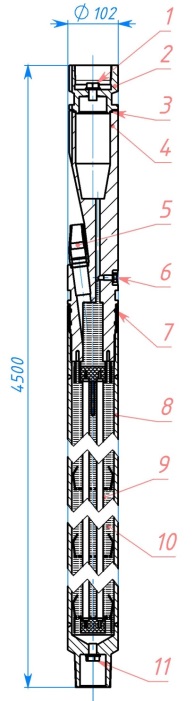

Bottom-Hole Area Heating Unit design

Bottom-Hole Area Heating Unit design

- Filler neck

- Internal connecting thread of bare tubing НКТ Ø73 ГОСТ 633-80

- Upper head body

- Compensation expansion chamber

- Current feedthrough jig

- Neck of heat conductor level

- Heater body

- Internal measuring element of heater

- Heating components

- Heat conductor

- Drainage hole

Putting the heater directly into the perforation interval allows you to warm not only the borehole fluid but also some space of bottomhole formation zone, in particular – perforation channels resulting in cleaning of channels from thickened fraction and consequently, increase of oil drainage.

Oil flow along the body of heater of temperature from 50° to 200°С makes it possible to increase the temperature of borehole fluid near a pump up to 50°С in comparison with initial meaning. Considering that borehole fluid viscosity becomes twice as little at heating by 10°С, pump load decreases consequently. Pump load reduction brings to significant increase of overhaul life.

Control station makes it possible to choose suitable temperature mode resulting in solution of another problem - wax deposition of downhole equipment, that also has a positive impact on operating time of well.

Owing to increasing the temperature of borehole fluid leading to decrease of oil viscosity and pump load, flow capacity of tubing increases and as consequence well production rate increases.

Also while daily sampling borehole fluid, oil property improvement was found.

![]()

Use of standardized electrical connectors, couplings, current feedthrough and power cables provides simplicity of maintenance of Bottom-Hole Area Heating Unit immediately at wellsite.